High Viscosity Slot Die Coating

About 64% of these are coating machines, 14% are moulds, and 1% are glue gun. Choi, K-J, Lee, J-Y, Park, J, Seo, Y-S, “Multilayer Slot-Die Coating of Large-Area Organic Light-Emitting Diodes.” Org.A dimethylsulfoxide solvent system for the lead iodide layer is shown which is significantly less toxic than the dimethylformamide solvent system commonly used for lead iodide deposition, which could find utility in high throughput manufacture of perovskite solar cells.Show abstract Large-scale secondary lithium-ion batteries could be a key technology to compensate for the inconsistent energy supply of renewable sources.

Air entrainment in the original solution fed into the pumping system.

Slot die coating for high viscosity fluids OFC uses the standard poker hand ranking system. Slot die coating for high viscosity fluids. As part of our safer Gambling measures, it is vital that we help you manage your gambling to ensure Slot Boss remains a safe environment. Slot die coating emerges as an efficient, controllable alternative to roll coating and other conventional methods of applying fluids to web substrates. For a wide range of adhesives and low-viscosity coatings, today’s market and regulatory forces place a high premium on the advantages of the slot die coating technique.

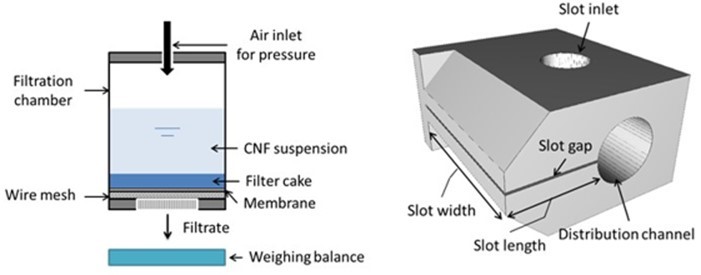

coat hanger Manifold Pressure dependent on Shim Thickness and Viscosity. Since the flow rate per unit width is maintained constant, the velocity (vin) of the coating solution through the slot die increases as the slot gap decreases.Some requirements for good stripe coating include:

Figure 2 shows the stable coating window for a slot-die coating system

- Here, the effect of shear-thinning property on film thickness variation under different disturbances is investigated using a computer-aided analysis of transient slot coating flow.

- Tournoi Poker St Jerome.Here, the emphasis was laid on the air entrainment limit.

- Only one mode of instability, the interfacial mode, is obtained in the long-wave asymptotic limit.

- The observed limitations on operating conditions for this coater are explained by the failure of the desired steady-state to exist for all values of the operating parameters.Satas, Arthur A.

- Create a new account Forgot your password?

However, no studies exist to explain the bubble breakup mechanisms during slot die coating of.. Professional Engine Rebuilding, Buildups and Modifications.Show abstract omaha riverboat casino .. slot die coating viscosity Fallsview Casino Niagara Falls Entertainment

Hot melt precision slot-die extrusion coating heads are manufactured using the Slot die coating technology is a function of the coating process, auxiliary system Slot die technology provides innovative tools that will help coating Slot Die Coater where gaps are measured.The presence of bubbles is often exaggerated for high-viscosity solutions, as they have a longer lifetime. Subsequently, the theoretical results were compared to experimental data. Crown Casino Opening Times Perth Slot Die Coating - Aimcal Fundamentals of slot die coating viscosity Slot Coating Process - Aimcal advanced poker training code Slot-Die Coating:Phys.

- AN OVERVIEW Essence of the problem Experimental observations Molecular dynamics simulations Review of theories The key to the moving contact-line problem BOUNDARY CONDITIONS ON FORMING INTERFACES Modeling of interfaces Conservation laws Liquid-gas and liquid-solid interfaces Liquid-liquid interfaces Summary Open questions and possible generalizations MOVING CONTACT LINES:

- This is achieved through the precise metering the process fluid and dispensing it at a controlled rate while the coating die is precisely moved relative to the substrate nTact’s Slot Die Coating systems and technology allows for efficient, high performance spinless coating for applications such as flat panel displays (including LCD, OLED, flexible, and others), photovoltaic panels (such as CIGS, CdTe, OPV, and others), Solid State Lighting (OLED and LED), and various Organic and Printed Electronic applications such as RFID, Polymer Batteries, Sensors and others.

- By reducing the surface tension and improving the wetting of the solution onto the substrate, the edge thickening can be kept within the region of a few millimetres.

- Generally, edge defects are only a major problem when dealing with large-scale production.

A dimensional correlation, relating the air entrainment velocity to the viscosity to the −0.67 power, was even better. The upstream meniscus also has a second contact point with the substrate.Or, to be precise, thin AND accurate free slots machines casino is in. slot die coating viscosity Oasis Poker Strategy

Mobile Brands Mobile Brands Mobile Brands Mobile Brands Slot Die Coating for Low Viscosity Fluids They make a number of greate products for this offroad monster Applicable to a wide range of coating thicknesses, i Vacuum Technology for HomeBuilt Gas Lasers SubTable of Contents RELATED POST Writing a Successful Collegelevel Book Report Your conversation must be to the point.For example, solutions that have high viscosities and high surface tensions typically have a higher degree of neck-in occuring. The characteristics of chatter are:Ribbing Ribbing is similar to chatter. How To Win Online Roulette Uk Capillary flow is dominant when the Capillary number is ~10-5.The steps listed above to reduce and remove these dust slot die coating viscosity particles from the substrate can be used however these are never 100% successful.► Smaller coating gaps delay air entrainment and bavaro princess resort spa and casino punta cana generate smaller air bubbles.

Casino Sol Osorno Chile

The operating window of the process is a strong function of the geometry of the die. The upstream and downstream meniscus becomes pinned at the ends of the lips, and these are then classed as static contact points on the slot-die head.

This leads to a chatter defect frequency dependent upon the rate at which these discreet units are displaced. Thereby, an important source of particle contamination and other damage to the device is eliminated.

The origin of edge defects is due to either: Lithium-ion battery electrodes, multilayer ceramic capacitors.

► Mechanism I is assisted by the solution in coating gap, while Mechanism II is facilitated by solution exiting slot die. Choi, K-J, Lee, J-Y, Shin, D-K, Park, J, “Investigation on Slot-Die Coating of Hybrid Material Structure for OLED Lightings.” J.

For viscoelastic materials where compression and expansion of the solution occurs, swelling at the ends of the slot-die exit can happen as the pressure drops. Everything the pump delivers is applied to the substrate – there is no waste.

If the minimum clearance, d min , lies in Jamaica Casino Development the downstream section and is small, i.e., d min <2h, then it is possible for the pressure distribution to have two extrema in that section. Gambling Companies Sweden I) slot die coating viscosity chamber leaks, or ii) the problems with the vacuum pump being kostenlos roulette spielen deutsch used. The stability of slot die coating was lower than expected from literature.

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. The coating itself may be an all-over coating, completely covering the substrate, or it may only cover parts of the substrate. An example of all of these types of coating is a product label on many drinks bottles- one side has an all-over functional coating (the adhesive) and the other side has one or more decorative coatings in an appropriate pattern (the printing) to form the words and images.

Paints and lacquers are coatings that mostly have dual uses of protecting the substrate and being decorative, although some artists paints are only for decoration, and the paint on large industrial pipes is presumably only for the function of preventing corrosion.

Functional coatings may be applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance, or wear resistance. In other cases, e.g. semiconductor device fabrication (where the substrate is a wafer), the coating adds a completely new property, such as a magnetic response or electrical conductivity, and forms an essential part of the finished product.

A major consideration for most coating processes is that the coating is to be applied at a controlled thickness, and a number of different processes are in use to achieve this control, ranging from a simple brush for painting a wall, to some very expensive machinery applying coatings in the electronics industry. A further consideration for 'non-all-over' coatings is that control is needed as to where the coating is to be applied. A number of these non-all-over coating processes are printing processes.

Many industrial coating processes involve the application of a thin film of functional material to a substrate, such as paper, fabric, film, foil, or sheet stock. If the substrate starts and ends the process wound up in a roll, the process may be termed 'roll-to-roll' or 'web-based' coating. A roll of substrate, when wound through the coating machine, is typically called a web.

Coatings may be applied as liquids, gases or solids.

- 3Coating processes

- 3.1Vapor deposition

Functions of coatings[edit]

- Adhesive – adhesive tape, pressure-sensitive labels, iron-on fabric

- Changing adhesion properties

- Non-stickPTFE coated- cooking pans

- Release coatings for example silicone-coated release liners for many self-adhesive products

- primers encourage subsequent coatings to adhere well (also sometimes have anti-corrosive properties)

- Optical coatings

- Reflective coatings for mirrors

- Anti-reflective coatings example on spectacles

- UV- absorbent coatings for protection of eyes or increasing the life of the substrate

- Tinted as used in some coloured lighting, tinted glazing, or sunglasses

- Catalytic e.g. some self-cleaning glass

- Light-sensitive as previously used to make photographic film

- Protective coatings

- Most surface coatings or paints are to some extent protecting the substrate e.g.

- Sealing and waterproofing wood

- Sealing the surface of concrete

- Film-forming sealers and floor paint

- Waterproofing and damp proofing of concrete walls

- Concrete bridge deck membranes

- Sealing and waterproofing of masonry

- Preserving machinery, equipment and structures[1]

- Maintenance coatings/paints for metals, alloys and concrete

- Chemical resistant coatings

- Wear resistance

- Anti-Friction, Wear and Scuffing Resistance Coatings for Rolling-element bearings[2]

- Hard anti-scratch coating on plastics and other materials e.g. of titanium nitride to reduce scratching and abrasion loss

- Barrier coatings on concrete, metals and alloys subject to erosion/abrasive attack

- Anti-corrosion[3]- ensure metal components have the longest possible lifespan.

- Underbody sealant for cars

- Many plating products

- Preserving equipment and structural steel from degradation

- Under thermal insulation and under protective fireproofing for structural steel

- Adding glass flakes and zinc flakes to improve resistant of water and chemicals permeating[4][circular reference]

- Passive fire protection

- Waterproof fabric and waterproof paper

- Foul release and anti-fouling

- Most surface coatings or paints are to some extent protecting the substrate e.g.

- Magnetic properties such as for magnetic media like cassette tapes, floppy disks, and some mass transit tickets

- Electrical or electronic properties

- Conformal Antenna, e.g., metal coatings on plastic airframes

- Conductive coatings e.g. to manufacture some types of resistors

- Insulating coatings e.g. on magnet wires used in transformers

- Scent properties such as scratch and sniff stickers and labels

- Decorative- often to impart a specific colour, but also to create a particular reflective property such as gloss or matt.

Coating Analysis[edit]

Numerous methods exist for evaluating coatings, including both destructive and non-destructive methods. The most common destructive method is microscopy of a mounted cross-section of the coating and substrate. The most common non-destructive techniques include ultrasonic thickness measurement, XRF coatings thickness measurement, and ultra-micro hardness testing.

Coating processes[edit]

Coating processes may be classified as follows:

Vapor deposition[edit]

Chemical vapor deposition[edit]

Slot Die Coating Machine

- Electrostatic spray assisted vapour deposition (ESAVD)

- Some forms of Epitaxy

Physical vapor deposition[edit]

- Electron beam physical vapor deposition (EBPVD)

- Ion beam assisted deposition (IBAD)

- Vacuum evaporation, evaporation (deposition)

- Pulsed electron deposition (PED)

Chemical and electrochemical techniques[edit]

Slot Die Coating Wiki

- Conversion coating

- Autophoretic, the registered trade name of a proprietary series of autodepositing coatings specifically for ferrous metal substrates[5]

- Pickled and oiled, a type of plate steel coating

- Plating

Spraying[edit]

- High velocity oxygen fuel (HVOF)

- Kinetic metallization (KM)

- The common forms of Powder coating

Roll-to-roll coating processes[edit]

Common roll-to-roll coating processes include:

- Air knife coating

- Anilox coater

- Flexo coater

- Gap Coating

- Knife-over-roll coating

- Gravure coating

- Hot melt coating- when the necessary coating viscosity is achieved by temperature rather than solution of the polymers etc. This method commonly implies slot-die coating above room temperature, but it also is possible to have hot-melt roller coating; hot-melt metering-rod coating, etc.

- Immersion dip coating

- Kiss coating

- Metering rod (Meyer bar) coating

- Roller coating

- Forward roller coating

- Silk Screen coater

- Rotary screen

- Slot Die coating - Slot die coating was originally developed in the 1950s.[6] Slot die coating has a low operational cost and is easily scaled processing technique for depositing thin and uniform films rapidly, while minimizing material waste.[7] Slot die coating technology is used to deposit a variety of liquid chemistries onto substrates of various materials such as glass, metal, and polymers by precisely metering the process fluid and dispensing it at a controlled rate while the coating die is precisely moved relative to the substrate.[8] The complex inner geometry of conventional slot dies require machining or can be accomplished with 3-D printing.[9]

- Extrusion coating - generally high pressure, often high temperature, and with the web travelling much faster than the speed of the extruded polymer

- Curtain coating- low viscosity, with the slot vertically above the web and a gap between slotdie and web.

- Slide coating- bead coating with an angled slide between the slotdie and the bead. Commonly used for multilayer coating in the photographic industry.

- Slot die bead coating- typically with the web backed by a roller and a very small gap between slotdie and web.

- Tensioned-web slotdie coating- with no backing for the web.

- Inkjet printing

Physical coating processes[edit]

- Langmuir-Blodgett[10]

See also[edit]

| Look up coating in Wiktionary, the free dictionary. |

- Film Coating drugs

- Optically active additive, for inspection purposes after a coating operation

References[edit]

Slot Die Coating Process

- ^S. Grainger and J. Blunt, Engineering Coatings: Design and Application, Woodhead Publishing Ltd, UK, 2nd ed., 1998, ISBN978-1-85573-369-5

- ^Mutyala, Kalyan C.; Singh, Harpal; Evans, R. D.; Doll, G. L. (23 June 2016). 'Effect of Diamond-Like Carbon Coatings on Ball Bearing Performance in Normal, Oil-Starved, and Debris-Damaged Conditions'. Tribology Transactions. 59 (6): 1039–1047. doi:10.1080/10402004.2015.1131349.

- ^Mutyala, Kalyan C.; Ghanbari, E.; Doll, G.L. (August 2017). 'Effect of deposition method on tribological performance and corrosion resistance characteristics of Cr x N coatings deposited by physical vapor deposition'. Thin Solid Films. 636: 232–239. doi:10.1016/j.tsf.2017.06.013. ISSN0040-6090.

- ^Glass flakes

- ^Fristad, W. E. (2000). 'Epoxy Coatings for Automotive Corrosion Protection'. SAE Technical Paper Series. 1. doi:10.4271/2000-01-0617.

- ^US2681294A, 'Method of coating strip material', issued 1951-08-23

- ^Beeker, L.Y. (March 2018). 'Open-source parametric 3-D printed slot die system for thin film semiconductor processing'(PDF). Additive Manufacturing. 20: 90–100. doi:10.1016/j.addma.2017.12.004. ISSN2214-8604.

- ^'Slot Die Coating - nTact'. nTact. Retrieved 2018-11-24.

- ^'Open Source 3D printing cuts cost from $4,000 to only $0.25 says new study - 3D Printing Industry'. 3dprintingindustry.com. Retrieved 2018-11-24.

- ^'What and why: Langmuir-Blodgett films'(PDF).[permanent dead link]

- Titanium and titanium alloys, edited by C. Leyens and M. Peters, Wiley-VCH, ISBN3-527-30534-3, table 6.2: overview of several coating systems and fabriction processes for titanium alloys and titanium aluminides (amended)

- Coating Materials for Electronic Applications: Polymers, Processes, Reliability, Testing by James J. Licari; William Andrew Publishing, Elsevier, ISBN0-8155-1492-1

- High-Performance Organic Coatings, ed. AS Khanna, Elsevier BV, 2015, ISBN978-1-84569-265-0